|

Metallurgical cause of failure analysis is performed using the practice described in the American Society for Metals Handbook, 9th edition, volume 11. A battery of tests are performed in stages while accumulating evidence that is reviewed and assessed by our engineers and technical specialists. An engineering report is prepared and submitted, including photographic evidence, which reports observations, findings and conclusions. A more detailed description of the analytical process is available from our metallurgical department.

Services

- Professional engineering

- Forensic metallurgy

- Welding engineering

- Metallurgical engineering

- Metallurgical quality assessment

- Scanning electron microscopy

|

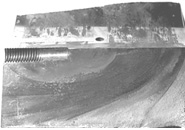

Rear axle fracture by overload

|

Recent Projects

- Pool heater heat exchanger failures

- Overloaded cracked sewer pipe

- New York City steam pipe explosion

- Sea wall tie bar failure

- Mechanical integrity of portable navy jet

- Fighter landing mats

- Socket wrench brittle fracture

|

Chloride stress corrosion cracking in a T304

stainless steel tank shell

|

Fatigue failure

|

Molten salt corrosion on

T409 bioler tube

|

Large gas holes in a

broken cast iron storm

sewer grate

|

|